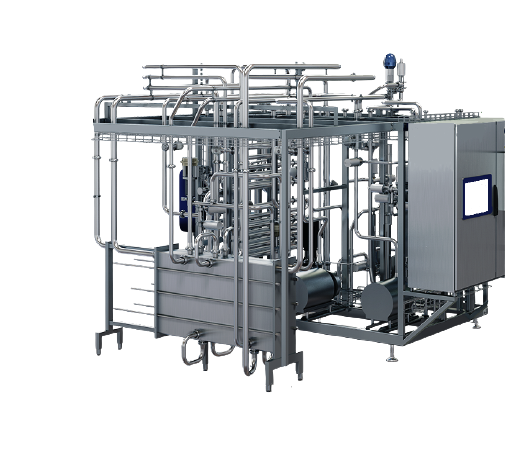

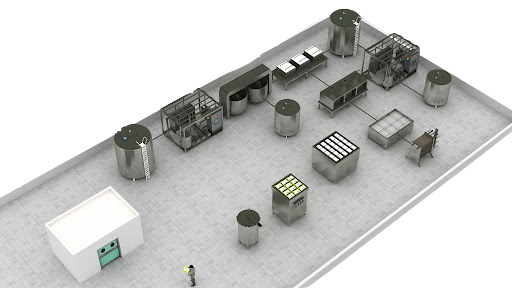

The Clean-In-Place (CIP) system is used in the sanitation of your process piping, tanks, and equipment. It allows users to automatically control the washing of equipment. Infinite Clean-In-Place (CIP) Systems are engineered to your specific plant application and utility requirements for effective and efficient process equipment cleaning. Proper CIP design and sizing ensure sufficient flow and appropriate pressure to thoroughly remove residue, rinse effectively, shorten cycle times, reduce operating costs and promote worker safety.