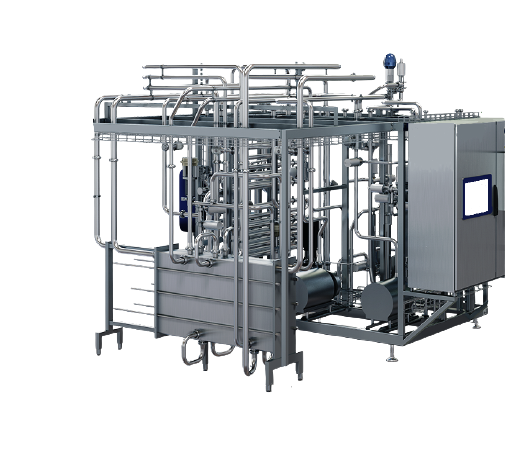

The Infinite Milk Pasteurizer unit features automatic control of pasteurization temperature, automatic flow diversion, and continuous recording for full traceability together with high heat recovery for low operating cost. Available in capacities ranging from 500 to 20,000 LPH, the Milk Pasteurizer is pre-assembled and factory-tested with water to ensure fast installation and commissioning for reliable performance and high ROI over a long service life. The pasteurization unit (HTST Pasteurizer) is designed for the thermal treatment of milk and dairy products and other food products such as soft drinks and juices. The process destroys pathogenic microorganisms by heating the product to a moderately high temperature for a brief period.